Individual solutions for your maintenance concept

Filter elements

Up to 1 µm: Excellent oil purity even surpasses new oil

The ultra-fine particle filtration up to NAS 1 (corresponds to ISO 4406: 13/10/7) provides the following benefits:

- Receives important components of the oil such as additives

- Absorbs up to 5 liters of water per element

- Keeps the oil from aging

- Works against contamination of the system

- Extends oil change intervals

- Ensures less failures (i.e. of servo valves)

3 sizes for different requirements

C-1000-filter: Maximum service life

C-750-filter: Long service life

C-500-filter: Low space requirement

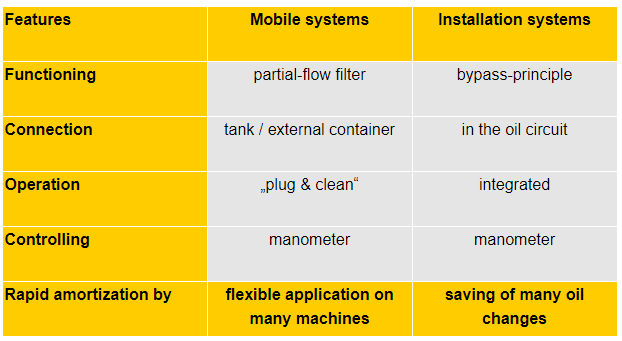

6 types of filters: The proper processing for each type of oil

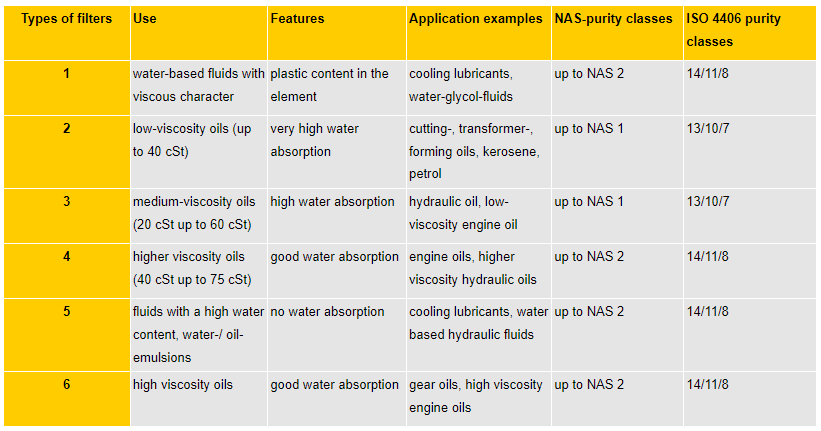

Installation system C 750 ES

Our installation systems with integrated safety control block are suitable for installation in pressurized lines.

The integrated safety control block consists of a volume flow reduction unit and a pressure reducing valve.

These two components make this system become a cost-effective, very safe, and technically fast operating solution.

The mounting to existing systems and machines can be completed in just a few minutes, because there are only 2 connections and mounting material is also part of the system.

Section through the safety control block with standard connections

of the volume control and the pressure reduction.

Installation system C 1000 ES

Our C 1000 ES cleans oil in the main flow with the purity of a partial-flow filter. The partial-flow filtration of technical oils is the most effective and cleanest way of filtration.

An ordinary main flow filter cannot remove very fine particles from the oil for kinematic and dynamic reasons, because it is exposed to the high pressure of the system.

In order to combine the benefit of the main flow filter – mounting in the main flow – with our excellent filter results, we have developed the installation system C 1000 ES. By use of a control block which consists (amongst others) of a pressure reducing valve and a volume flow control, we filter in the main flow with the results, which are even accepted in space travel since many years.

- Also available in stainless steel or plastic coating

- Ultra fine filtration in the main flow up to 1 µm particle size

- System pressure possible up to 360 bar

- Constructively simple to integrate, because the control block is installed on the housing

- Including a manometer for element and pressure control

- Including all fixing elements

Mobile ultra fine filter system M 121

The portable, mobile ultra fine filter system M 121 was especially created for small units and those difficult to access.

With the help of this robust design oil changes and the risk of spontaneous breakdowns can significantly be reduced.

By using our cost-effective 61 filter elements, high oil purity and the elimination of water in oil is guaranteed, despite low investment costs.

As the M 121 is portable, and driven by a 230 V- asynchronous motor, it is the optimal tool for flexible service work.

- 230 V asynchronous motor, contactless

- Stable gear pump

- Manometer for flow- and element control

- 24/7 – unattended operation

- Variable pressure regulation

- Transfer-circuit

- Flow regulation for high viscosity oils

- Including 1.5 meter flow-/return hose

- Easy operation: „plug & clean“

Mobile ultra fine filter system M 1201

The M 1201 is identical in construction to our M 1401 except for the power supply.

We equip this machine with a 220-volt-asynchronous motor with Steinmetz circuit for high flexibility in places where no 3-phase current is available. This way it can also be operated by a conventional generator in remote locations such as removed brines in quarries.

The M 1201 is also very easy to operate, it has selected components made in Germany, and the construction is very stable. We have consciously refrained from any electrical elements due to the usability and the reliability outdoors.

- 230 V-asynchronous motor, 0.55 kW, robust construction

- Stable gear pump, 14 liter/minute

- Manometer for flow- and element control

- 24/7 – unattended operation

- Transfer-circuit

- Flow regulation for high viscosity oils

- 2.50 m flow-/return hose

- Also suitable for high viscosity oils

Mobile ultra fine filter system M 1401

The M 1401 is the successor of our ultra fine filter system M1001, which has proven itself over a period of many years. The M 1401 is the all-rounder among the mobile filter systems.

Equipped with a robust pump unit, a scalper, and our proven hard chrome-plated C-1000 housing, this treatment system is an all-rounder. No matter which technical oil is to be processed, the M 1401 completes its tasks in the factory just as reliable as, for example, in a quarry.

It is extremely easy to operate, has selected components from German production, and was very robustly designed.

- 400 V-asynchronous motor, 0.55 kW, robust construction

- Stable gear pump, 14 liter/minute

- Manometer for flow- and element control

- 24/7 – unattended operation

- Transfer-circuit

- Flow regulation for high viscosity oils

- 2.50 m flow-/return hose

- Also suitable for high viscosity oils

Stationary ultra fine filter system S 1401

The S 1401 is a stationary ultra fine filter system for connection to the control cabinet and for constant processing of technical oils.

It runs completely independent with a motor-/pump unit. Especially on machines with continuous dirt- and water contribution it guarantees highest oil purity in the whole system.

Integration into the control system of the machine enables setting of flexible processing times.

These systems can also be manufactured due to individual installation

- 400 V-asynchronous motor, 0.55 kW, robust construction

- Stable gear pump, 14 liter/minute

- Manometer for flow- and element control

- Robust design, very loadable

- 24/7 – unattended operation

- Transfer-circuit

- Flow regulation for high viscosity oils

- 1.50 m flow-/return hose

- Also suitable for high viscosity oils

measures on request.

Mobile ultra fine filter system M 1411

Our M 1411 is the ideal machine for processing expensive cutting oils with swarf contamination. It has a pre-filter housing with a metallic screen cylinder and a three-way polypropylene pre-filter.

These two pre-filter units work together for retention of coarse impurities such as swarf or larger sand grains. The pre-filter can be used several times. This significantly extends the service life of our filter elements once again, which is already very long.

This system is also constructed very solidly, easy to operate, and completes its tasks without supervision.

- 400 V-asynchronous motor, 0.55 kW, robust construction

- Stable gear pump, 14 liter/minute

- Manometer for flow- and element control

- Robust design, very loadable

- 24/7 – unattended operation

- Transfer-circuit

- Pre-filter selectable from 5 µm – 800 µm

- Pre-filter can be used several times

- Also suitable for high viscosity oils

- 2.50 m flow-/return hose

Mobile ultra fine filter system M 110

Our mobile ultra fine filter system M 110 is a

processing machine for oils with coarse impurities such as swarf and suspended solids. Equipped with a washable pre-filter, coarse impurities are kept away from the main filter which significantly increases its life service once again.

It is constructed very robust and is easy to operate.

The vacuum display on the pre-filter enables an unattended continuous operation after switching on. An automatic pressure control and shutdown are also standard equipment of the M 110. In the processing of cutting oils for example, it stands for extremely short amortization times.

- 230 V-alternative 400 V motor, robust and reliable, stable gear pump

- Manometer for flow- and element control and for vacuum display in the pre-filter

- Pressure switch for selection setting in unattended operation

- 24/7 – unattended operation

- Pumping without filtration (transfer)

- Flow regulation for high viscosity oils

- Element lifter for simple and fast element exchange

Mobile ultra fine filter system M 120

Our mobile ultra fine filter system M 120 is the processing machine for larger oil volumes. Its two hard chrome-plated housings can filter up to 2.100 liter per hour of flow.

The robust construction, the easy operation, and the possibility of using it in continuous operation without supervision makes it an ideal tool of a preventive maintenance strategy for large units.

Even while filling new oil in larger systems it eliminates condensed water and foreign particles reliably. The high flow guarantees a short amortization time due to cost savings in fresh oil, oil changes, and repairs.

- 230 V-alternative 400 V motor, robust and reliable, stable gear pump

- Manometer for flow- and element control

- Pressure switch for selection setting in unattended operation

- 24/7 – unattended operation

- Pumping without filtration

- Flow regulation for high viscosity oils

- Element lifter for simple and fast element exchange

Mobile ultra fine filter system M 130

Our mobile ultra fine filter system M 120 is the processing machine for larger oil volumes. Its two hard chrome-plated housings can filter up to 2.100 liter per hour of flow.

The robust construction, the easy operation, and the possibility of using it in continuous operation without supervision makes it an ideal tool of a preventive maintenance strategy for large units.

Even while filling new oil in larger systems it eliminates condensed water and foreign particles reliably. The high flow guarantees a short amortization time due to cost savings in fresh oil, oil changes, and repairs.

- 230 V-alternative 400 V motor, robust and reliable, stable gear pump

- Manometer for flow- and element control

- Pressure switch for selection setting in unattended operation

- 24/7 – unattended operation

- Pumping without filtration

- Flow regulation for high viscosity oils

- Element lifter for simple and fast element exchange

For large oil reservoirs: M 501

The M 501 is a cleaning system for larger or centrally accruing amounts of oil. It eliminates up to 20 liter water and up to 12 kg particles of dirt with a flow of up to 4.800 liter/hour.

The M 501 consists of a large C-1200 housing and carries the oil about 1.5 meter purely axially through the filter elements. This achieves oil purity that can absolutely compete with fresh oil.

The M 501 is alternatively also available with two housings and a flow of 9.000 liter for time-critical applications or even larger volumes.

- 400 V asynchronous-motor, 2 kW power

- Robust, stable gear pump

- Manometer for flow- and element control

- Pressure control for unattended operation

- 24/7 – unattended operation

- Transfer-circuit

- Flow regulation for high viscosity oils

- Crane and element lifter for fast and easy filter exchange

For large oil reservoirs: M 504

Our oil reservoir cleaning system M 504 has the capacity of cleaning large oil containers like large tanks and reservoirs, and to store enormous amounts of water and dirt.

The M 504 consists of 4 large C-1200 housings and achieves a flow of nearly 300 liter per minute. Due to the large filter elements (1.5 m purely axial flow) this machine is the solution to re-obtain an oil quality in reservoirs in fresh oil condition or better.

The M 504 is specified separately for each customer- specific use. It can also be delivered in the mobile version (see figure) if needed.

- 400 V asynchronous-motor

- Robust, stable gear pump, 6.5 kW

- Manometer for flow- and element control

- Pressure switch for selection setting in unattended operation

- 24/7 – unattended operation

- Transfer-circuit

- Flow regulation for high viscosity oils Element lifter for fast filter exchange

- Including crane for easy filter exchange

Oil recycling system RS 6000

The system RS 6000 is a high-performing recycling system that cleans large oil volumes in several process stages. This system was constructed for many years of reliable work without service.

By several process steps such as heating and settling, large amounts of water and dirt are removed. Additionally, the usage of settling technology and a pre-filter increases the service life of the main filter.

The RS 6000 can be operated manually, semi- automatic, and fully automatic.

It is the ideal recycling system for central treatment of, for example, cutting oil or cooling lubricants.

- 400 V asynchronous-motor

- Robust, stable gear pump

- Free choice of settling- and heating times and the number of filter passes

- Either manual, semi-automatic, or fully automatic operation

- Displays for operation- and process status

- Flow regulation for high viscosity oils

- Element lifter for fast filter exchange